When it comes to understanding how to wire a solenoid, it is important to know the basic components and their functions. A solenoid is an electromechanical device that converts electrical energy into mechanical movement. It consists of a coil of wire wrapped around a core, which when energized, creates a magnetic field that moves a plunger or armature. Solenoids are commonly used in various applications such as automotive starter systems, industrial machinery, and automation systems.

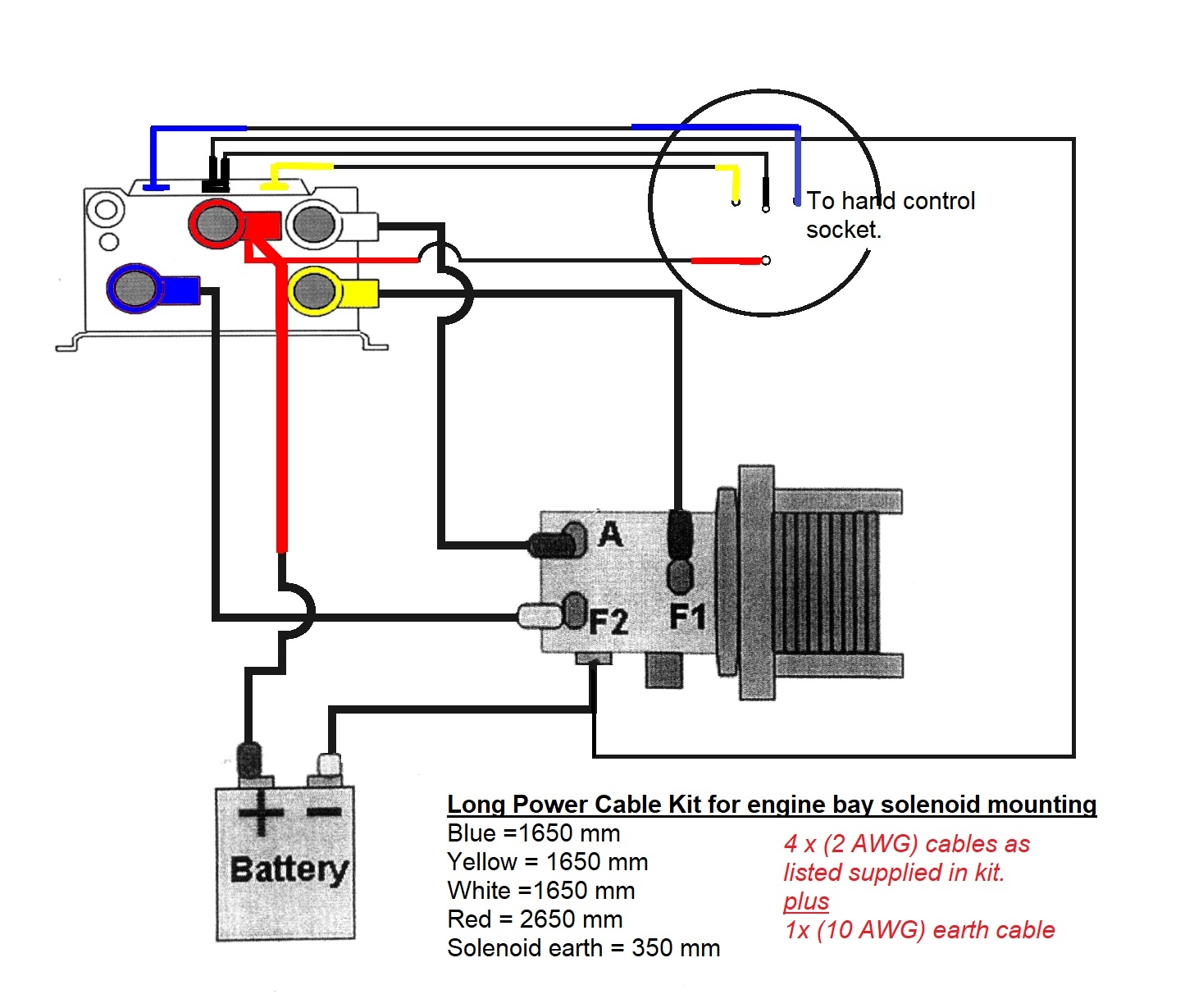

Understanding the wiring diagram for a solenoid is crucial for proper installation and operation. The diagram typically shows the connection points for the power source, ground, and load. It also indicates the polarity of the connections and any additional components such as diodes or resistors that may be required for proper functioning.

When wiring a solenoid, it is important to follow the manufacturer’s instructions and adhere to safety guidelines. Incorrect wiring can lead to malfunction or damage to the solenoid and other components in the system. It is recommended to use the appropriate gauge of wire and connectors to ensure a secure and reliable connection.

In a typical wiring diagram for a solenoid, the power source is connected to one terminal of the coil, while the other terminal is connected to the load. The ground connection is typically made to the metal frame or chassis of the device. Additional components such as diodes may be connected in parallel to the coil to protect the circuit from voltage spikes or reverse currents.

It is important to test the wiring and connections before applying power to the solenoid. This can be done using a multimeter to check for continuity and proper voltage levels. Once the wiring is verified, the power can be applied to energize the solenoid and test its operation. Any abnormal behavior or issues should be addressed immediately to prevent further damage.

In conclusion, understanding the wiring diagram for a solenoid is essential for proper installation and operation. By following the manufacturer’s instructions and safety guidelines, you can ensure a reliable and efficient system. Regular maintenance and inspection of the wiring connections are also recommended to prevent any potential issues. With the right knowledge and care, a solenoid can provide years of trouble-free operation in various applications.